So I wanted to make a video to show off this new part of Joshua Tree Mug Company, but I’m both too afraid to be on camera in front of you all and am so busy making mugs and designing new stuff that I just can’t seem to find the time to get it done. So….. this will have to be the big announcement!

We have gone to solar here at the print shop!

Yes, all our mugs are now pressed using solar power, exclusively. We have 500 watts of solar panels charging a deep cycle battery and a 3000-watt inverter powering our mug presses. So far we have been able to completely fill all the orders for mugs, coasters, and mousepads with the solar power we are generating.

When our batteries are full we divert the excess solar power to for our web and database servers that run the Joshua Tree Mug Company website.

I’ll be taking so pictures and posting them here in this blog entry really soon, but I just got an idea for a new mug design so I better jet now and get it done before I forget it!

Would you like to participate in our solar project? buy one of our mugs and you’ll be as green as we are 😇

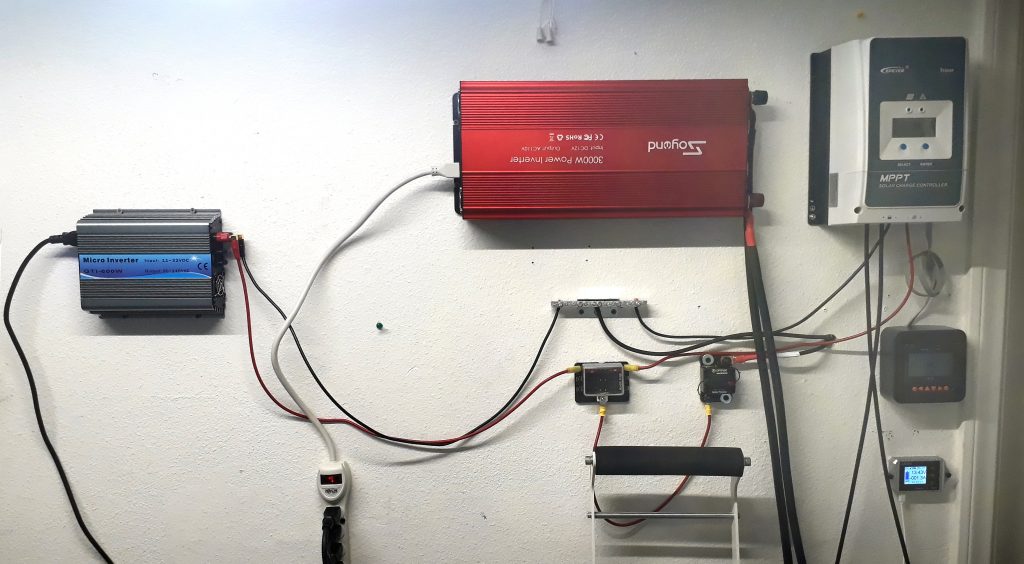

Edit: Here is a picture of our system. We have ~500 of 12v solar panels running to this setup. They currently yield about 1kwh per day.

Edit: February 8, 2020 – We’ve added more panels to our solar array and can now run our web and database servers full time on renewable energy! We are on our way to full energy independence!

Update: February 29, 2020 – Happy Leap Year! Yesterday We started testing our new 15k Watt inverter. It should run most of our buildings needs. We now have a total of 18 panels up and running.

This morning at 08:11 am we were pulling a total of 1.4 kW to recharge the batteries from overnight use. Yesterday afternoon we got to 40 amps on the charge controller running one of the solvent printers straight from solar. (It’s time to add another charge controller)

This Tuesday we also installed the load center that took the servers and data center off the grid permanently.

Update: April 12, 2020

I know I haven’t updated this post in a while, but We’ve been busy around here. Even with the Covid Virus outbreak, we’ve been using the time to build out the off grid solar system and move circuits slowly to it as we assess the battery and load capabilities.

I’m going to write a separate blog on how I recommend any individual business or family starts a project like this. I think I have some unique insights that are off of the normal path.

I haven’t been keeping track of exactly what this project has cost as we have several of our clients that are helping with the expenses, but to date the total investment has been in the neighborhood of $15,000.

We now generate somewhere in the ball park of 25 kWh per day between win and solar between 3 different systems: a 48 volt DC primary system with a 15k watt split phase 220 volt ac inverter, a 12 volt DC heat press system with a 3000 watt 110 single phase inverter for making Dye Sublimation products and lastly a small grid tie inverter running any left over 36 volt solar panels that don’t fit onto an array. The latter system will be phased out as we have completed the transition of both our power meters to the off grid inverters.

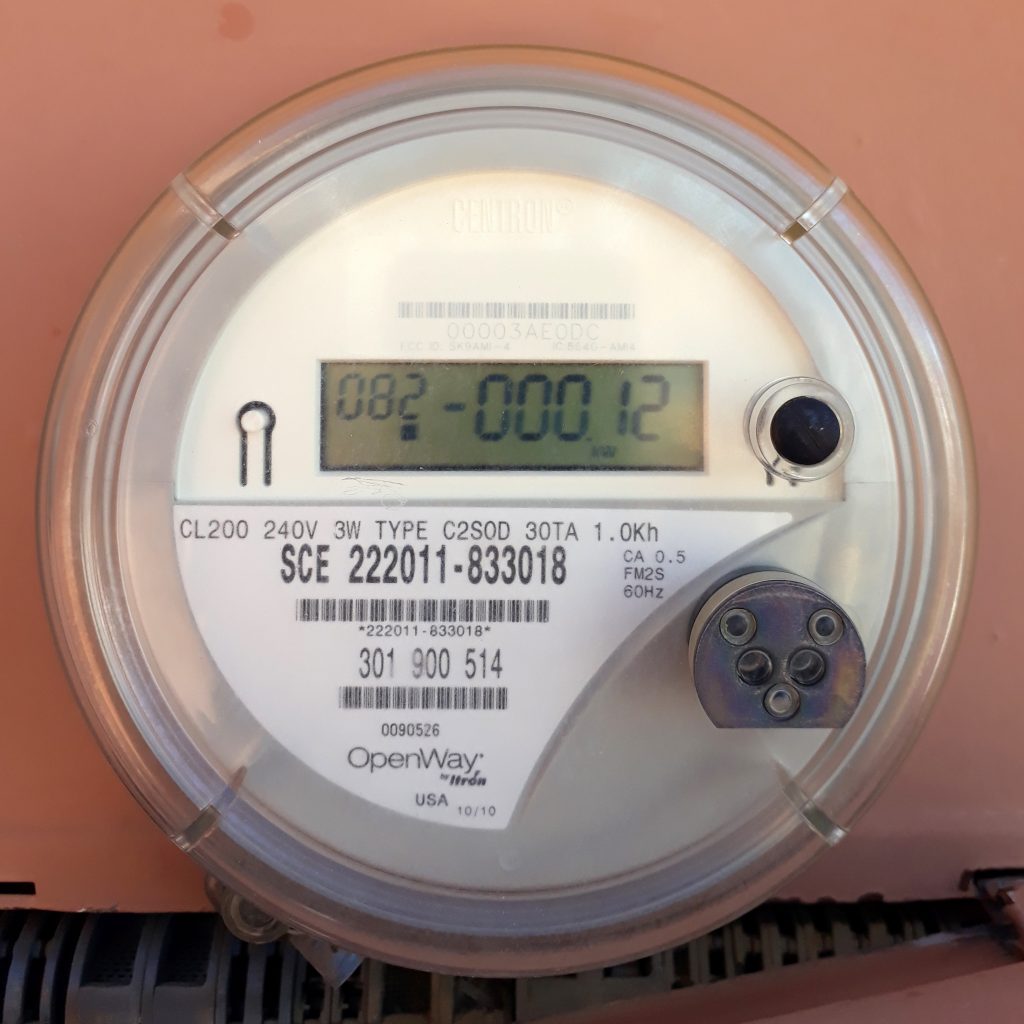

I decided to update today because as I was moving a couple circuits around I glanced at our secondary SCE meter and saw this:

Apparently with our sales office computer and lights taken off the grid and moved to solar we now have excess power on the grid tie system, occasionally, which we give to SCE, as we do not have a net metering agreement to sell them the power.

We are now very close to being completely energy independent!

Update: May 3, 2020 –

WE ARE OFF THE GRID!

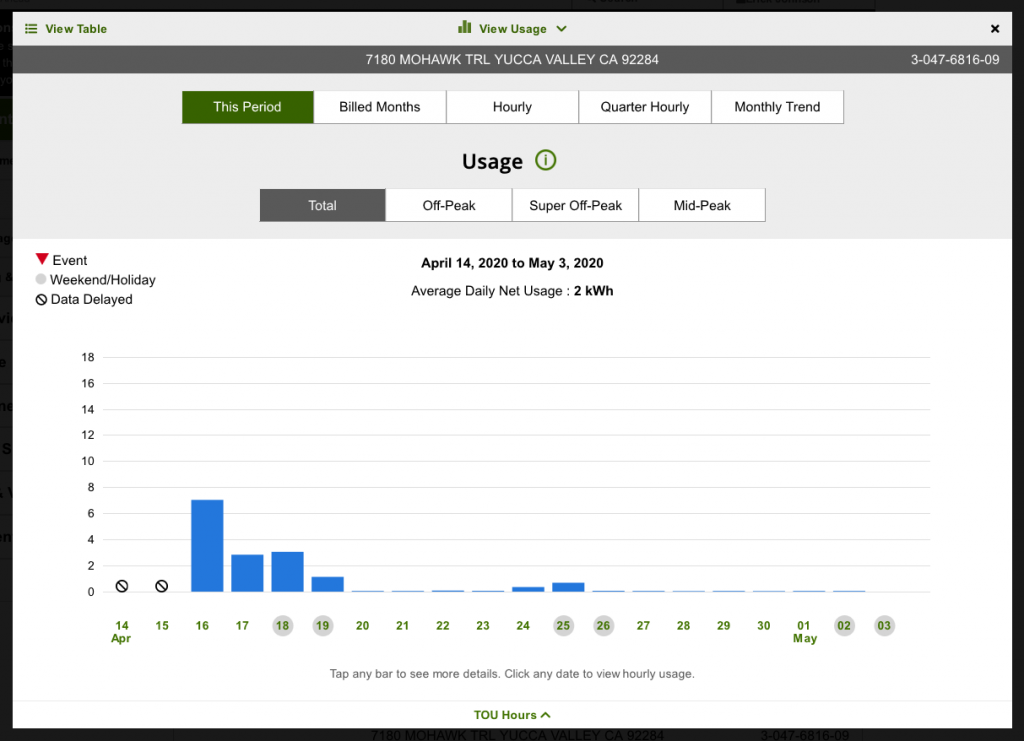

Over the last two weeks we have been testing our final configuration and have used no power from SCE, as the usage graph below shows.

SCE Usage Graph

We now have 10kW of solar panels on the roof, but summer is coming faster than we expected and air conditioning is going to be necessary soon, so it is now a race to see who is faster – Mother nature or us putting up panels.

We have 75 more 270 watt panels to install to add an additional 20kW of solar. It will take a bit more work, but it is doable before we need to turn the AC on.

We have completely retrofitted the old circuit breakers in the building and added the additional circuits required for our printers to all run at the same time.

The next step is to add a complete “power station” in a climate controlled shipping container on the side of the building. Large inverters make lots of noise and it will be nice to get them out of our working space. It will also be nice to get the more than 2000 amp hours of batteries we need to run through the night into a climate controlled environment to extend their lifetime.